Ask RideMan

#5 — Restraints

What is the mechanism that causes the restraints on roller coaster trains to lock in place then release once the ride is over? Is this mechanism changed on newer coasters from what it has been on older ones? And when riders have to be evacuated away from the station — either from a lift hill or a brake run — how do operators disengage the restraints?

— Perpetual Obsession

The primary requirement for the restraint system on a roller coaster is that it be secure and effective. There are a couple of requirements spelled out in the ASTM standards, particularly F2291-14 section 6, which lays out certain specifications. Mostly, the standards require that the ride have restraints appropriate to the ride actions and to the expected passengers. There is also a requirement for a manual restraint release. Not that any reasonable designer would honestly consider building a ride without one.

Perhaps the most important requirement is that the system be reliable. For that reason, most rides make use of redundant, failsafe mechanisms that will reliably lock the restraints in position. For that reason, the mechanisms have not changed a lot over the years. Most rides use relatively simple mechanical means for locking lap bars and shoulder bars in place. Some rides use a combination of mechanical and hydraulic systems, and the most recent systems generally use hydraulic locking systems.

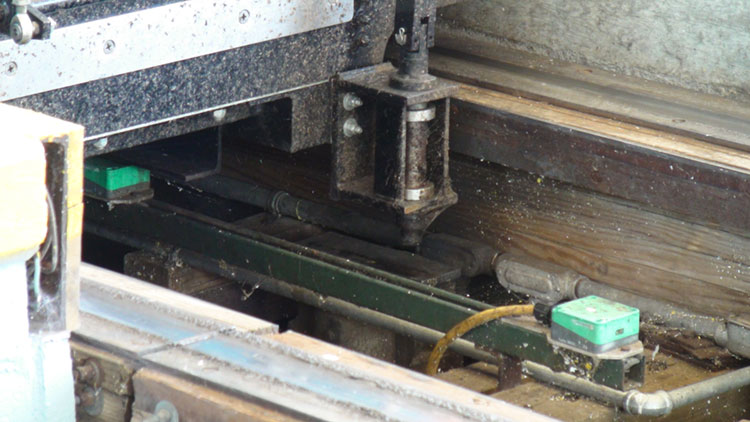

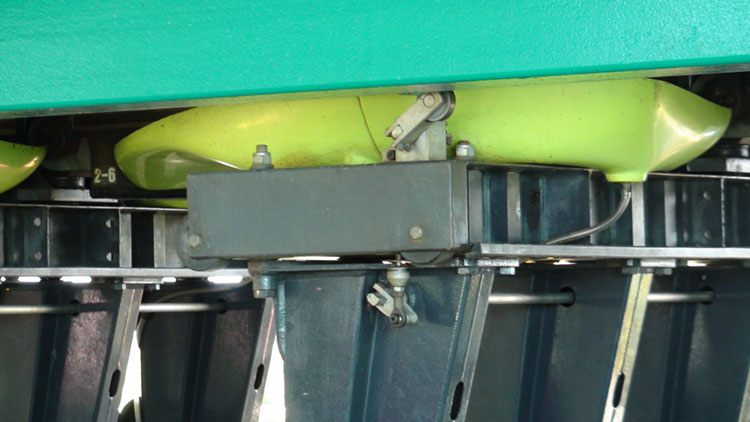

In recent years, we’ve seen a shift to passive hydraulic restraints, which have certain benefits over older mechanical systems. First, the hydraulic systems are infinitely adjustable, and can be plumbed to offer a ratcheting action. Second, certain European manufacturers are now offering the locking mechanism — a hydraulic cylinder, an attached bladder accumulator to both handle the excess fluid as the rod retracts and serve as a return spring, and a solenoid valve — as a pre-manufactured self-contained component that can be bolted into nearly any ride.

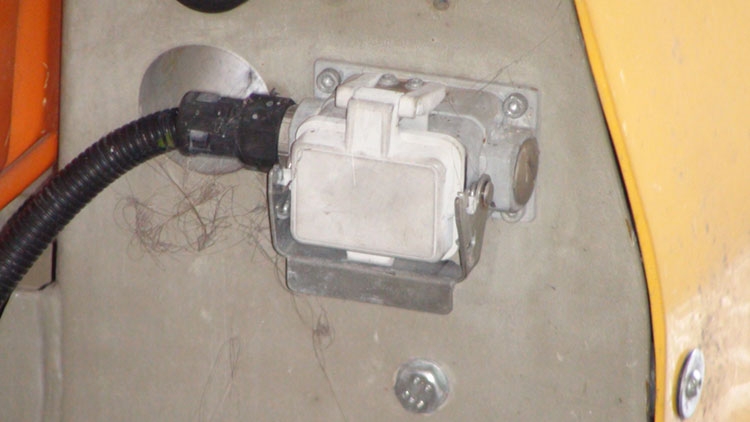

By mounting the assembly in different ways, the same locking cylinder can be used for a shoulder bar or a lap bar. Accordingly, we see more or less the same locking cylinders used on Shoot the Rapids, Maverick, Top Thrill Dragster, Wicked Twister and Millennium Force. Generally, two cylinder assemblies are used, each one serving as a redundant backup for the other (here’s an example). That’s not the actual mechanism used on the Intamin coasters, but it is a similar unit. The Intamin units are built by Oelhydraulik Hagenbuch AG of Switzerland.

But the increased use of hydraulic cylinders does not mean the older mechanical designs are any less reliable. Blue Streak, Mine Ride, Gemini, Magnum XL-200 and Mean Streak all use all-mechanical lap bar systems. Corkscrew is an interesting case. When the ride was new, it had a hydraulic cylinder system that was backed up with a mechanical latching mechanism. Over the years I believe it has been converted to an all-mechanical system.

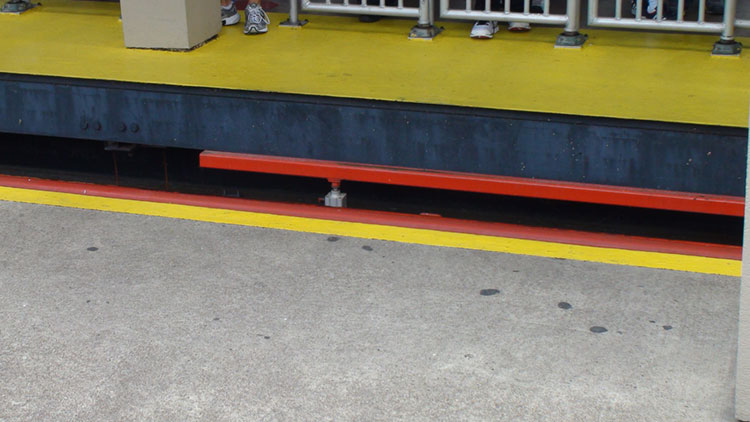

On most coasters (Corkscrew and Mine Ride are the notable exceptions), there is some mechanism in the station to lock and unlock the restraints. There are two basic systems on the Cedar Point coasters: mechanical systems, where a rod or plunger, usually pneumatically operated, in the station pushes against a lever on the train to release the restraints, then releases to lock the restraints again; and electrical systems where electrical contacts in the station operate control valves on the hydraulic locking cylinders.

Blue Streak

A plunger under the front of each train opens the lap bars.

Gemini, Iron Dragon, Magnum XL-200, Raptor, and Rougarou

Bars under (or over for the case of Raptor) the cars are moved up and down to open and lock the restraints.

Mean Streak and Woodstock Express

Bars on the sides of the station push the release plungers on the side of the train to unlock the lap bars.

Millennium Force, Wicked Twister, Top Thrill Dragster and Maverick

Electrical contacts are pushed into contact with the train to operate the restraints, and in some cases (Maverick) to feed back the restraint status to the ride controls.

GateKeeper (and presumably Valravn)

Spring-loaded contacts on the track connect with pins on the train to operate restraint valves and feed restraint status back to the ride controls.

Manual Release Systems

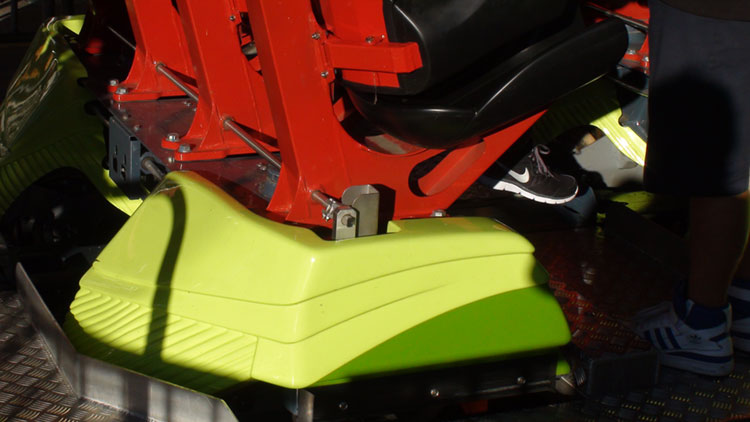

Of course all of these rides have some form of manual release system. On most rides, it’s a foot pedal mounted on the front or back of each car. On Mine Ride and Corkscrew, there is no automated system for opening and closing the lap bars, so the manual release pedals are used in the station. All of the Arrow coasters — Mine Ride, Corkscrew, Gemini, Iron Dragon, and Magnum XL-200 — have foot pedals that release all of the restraints in each car. The earlier B&M rides, Raptor and Rougarou, have a mechanical linkage that can be tripped manually either by pushing on the station release lever, or by slipping a small handle onto the end of the link rod. The new hydraulic systems are set up with a solenoid valve so electrical power is needed to open the restraint. This is usually provided (outside the station) by a battery box that attaches to a connector on the car. For Mean Streak and Blue Streak, a small hook can be used to manually lift the locking pawls on the lap bar lock, but both rides have also been equipped with foot pedals on the front of each car to release the lap bars.

Corkscrew

Cedar Creek Mine Ride

Perhaps the biggest change to happen in recent years is the addition of status reporting to the lap bar assemblies. Since the mid-2000’s, there has been a kind of a nebulous requirement which is now in ASTM F2291-14:6.4.3.8(5) to provide

“an external correct or incorrect indication”

with a further requirement that

“Detecting the failure of any monitored device shall either bring the ride to a cycle stop or inhibit cycle start.”

What that means is that there needs to be a means for checking that the safety restraint is locked, and I believe manual checks and external safety belts attached to the restraint (as on the B&M coasters) satisfy this requirement, as do lap bars that open automatically when unlocked (as on the Intamin coasters). Corkscrew is a special case because its manually operated restraints could potentially be left in the unlocked position at the start of the ride, so from the very beginning, Arrow included a system that would count the release pedals as the train exits the station and shut down the lift hill if one or more of the pedals are in the wrong position.

Except for Corkscrew and Mine Ride, all of the coasters now have mechanical restraint systems that automatically switch to the ‘locked’ position when the external release system is disconnected, so there is no real need to check for the locked position as the train leaves the station. But ride designers are now being more cautious than ever. While is is not explicitly required by the standard, more and more rides are including a restraint position detection system, and using a circuit loop to send that information back to the ride control system. That can be as simple as putting a switch on each restraint and tying them all together in a series loop so that the ride control system gets a simple READY indication from the train, or as complex as providing a separate signal for every seat on the train. Or anything in between.

On maXair and Windseeker, the restraint loop covers a group of seats for each indicator. The trade-off, of course, is that with the simpler system, only one input on the control system is needed, but operationally it’s a game of hide-and-seek to find the offending restraint. The more complicated system requires some means of getting a signal back to the control system for every seat, but the operators can tell immediately which seat isn’t properly locked. Both of these configurations are in use at Cedar Point: Maverick has lap bar position detection for the entire train, while GateKeeper has indications for each seat.

Bonus Video

This video shows a variation on the “Arrow Dance” in which an operator kicks the pedals on the Double Loop at Geauga Lake to release the shoulder bars as the train enters the station. To the best of my knowledge this was never done at Cedar Point.

Additional Resources

- ASTM F2291

- Standard Practice for Design of Amusement Rides and Devices

Dave Althoff, Jr.

Dave Althoff is a multimedia specialist, systems engineer and amusement industry consultant from Columbus, Ohio. Dave is a member of ASTM International and the National Association of Amusement Ride Safety Officials (NAARSO) and is an NAARSO Certified Amusement Ride Safety Inspector Level I (Basic). He has consulted on amusement ride design projects and ride operation controls and is listed as a co-inventor on United States Patent #7,905,789, “Specialized Restraint Systems for Amusement Rides.”

Have a question? Ask RideMan!

“Ask RideMan” is a PointBuzz feature where Dave Althoff answers your questions about the inner workings of rides and roller coasters.

Have a question you’d like to see answered? Email Dave at rideman@davealthoff.com.